description

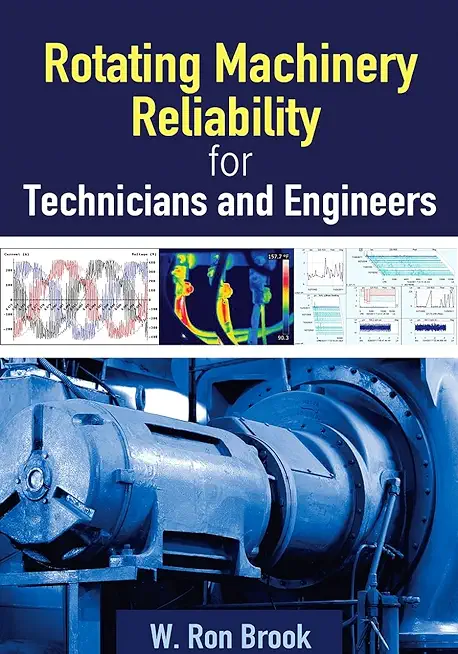

9Because many companies expend so few resources on training, new engineers, technicians, and analysts are often ill-prepared to tackle real-world problems and produce real-world solutions. And when it comes to large, expensive machinery, every minute of downtime can translate into the loss of millions of dollars.

Rotating Machinery Reliability for Technicians and Engineers is a compilation of those problems encountered daily by large manufacturers, delving deep into machinery fault analysis, with a concentration on vibration, bearings, and electrical issues that cause large problems. The work contains more than 50 case studies with the actual data and solutions, along with industry standards and best practices, covering what works, and perhaps more importantly, what doesn't work--all the result of the author's 45+ years in the field. It features a chapter on diagnosing and solving electric discharge machining damage in ball bearings.

Rounding out the incredible package is an affiliated website, www.rotatingmachinereliability.com, with invaluable resources for the technician and engineer:

Rotating Machinery Reliability for Technicians and Engineers is a compilation of those problems encountered daily by large manufacturers, delving deep into machinery fault analysis, with a concentration on vibration, bearings, and electrical issues that cause large problems. The work contains more than 50 case studies with the actual data and solutions, along with industry standards and best practices, covering what works, and perhaps more importantly, what doesn't work--all the result of the author's 45+ years in the field. It features a chapter on diagnosing and solving electric discharge machining damage in ball bearings.

Rounding out the incredible package is an affiliated website, www.rotatingmachinereliability.com, with invaluable resources for the technician and engineer:

- On-the-job videos, detailing exact specifications for analysis and troubleshooting.

- Spreadsheets for designing dynamic absorbers, estimating thermal growth, and calculating steel balance weight and weight removal

- Technical white papers on the elimination of electrical discharge damage and designing rotating machinery foundations

- Directions for implementing the latest technology using amplified motion to quantify operation deflection shapes.

- This is the book I wish I had when I started in the industry."

- "Hands-down the best work I've ever seen, making difficult concepts easy to understand, and offering tremendous value to beginners and experienced techs/engineers alike."

- "A must-read for anyone involved in rotating equipment reliability, especially new technicians."

- "A wonderful, helpful tool that has helped my team understand how to troubleshoot vibration issues in the field."

- Shows how analysts of 5 or 50 years in the field can help themselves in their approach to investigating potential issues in plant machinery."

member goods

No member items were found under this heading.

Return Policy

All sales are final

Shipping

No special shipping considerations available.

Shipping fees determined at checkout.